Welcome to FROZENBAR!

No1 catering equipment & mixtures company in Europe since 2011!

Products

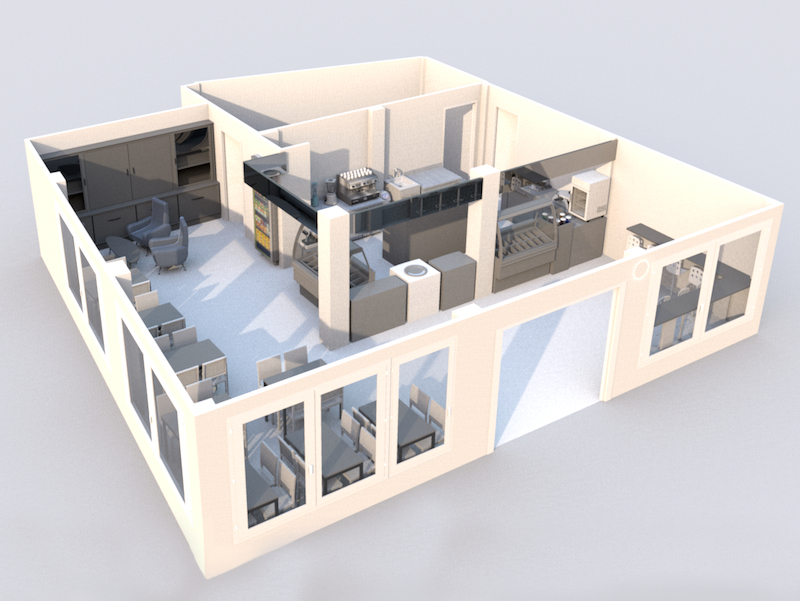

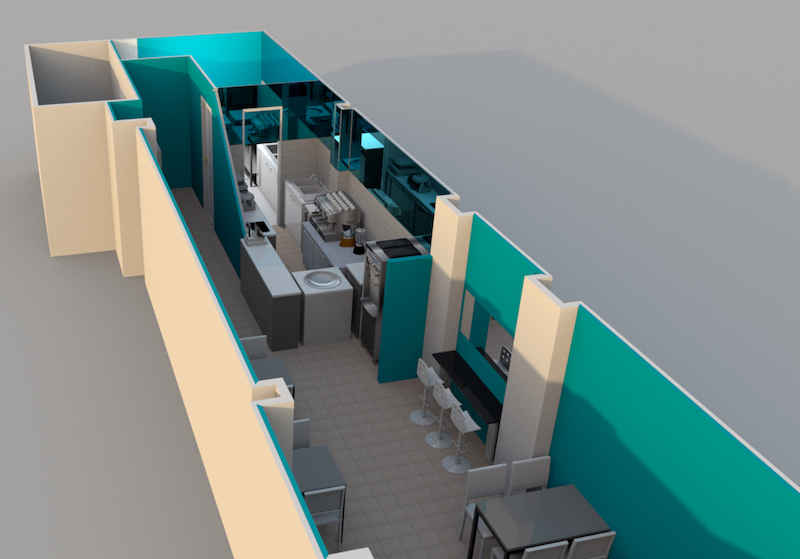

Analyze and create your next shop!

We create your successful store! We are with you from the initial space design to the complete equipment setup. Contact us to design the store of your dreams, tailored to your space

Catering Equipment

We supply and advise foodservice establishments, offering all the necessary equipment you’ll need. From kitchen and production equipment to front-end serving machines, we’ve got you covered.

Inhouse service

We provide in-house servicing for all our machines and maintain a ready stock of spare parts for every machine.

Why FrozenBAR

Quality Guarantee

We guarantee the quality of both our equipment and raw materials. Our primary concern is maintaining high quality at every stage, from the initial construction of your establishment to the daily supply of raw materials. All of this is offered at affordable prices that provide significant profit margins for your store.

Innovation

FrozenBAR offers innovative catering equipment along with the finest bakery and confectionery ingredients. Our product range caters to a wide spectrum of establishments, from cafes and refreshment bars to hotels. On our website, you’ll find the complete selection of innovative catering equipment and our exceptional quality ingredients.

Know How

The high expertise of FrozenBAR and our experience in the hospitality industry will assist you in making the best choices for your business, saving you valuable time and money. Our experience in both constructing establishments from scratch and equipping them ensures you will have nothing but positive experiences.